Some Mellow owners are asking for new innovations from Mellow. Even though the answer seems to be pretty easy, due to the "highest quality approach", it is a result of the complexity of problems.

Sorry for no 4x4, new wheel colours, app upgrade, larger battery or a scooter release for the mass market, but we are focusing on the Mellow Drive from a production and financial perspective.

We want it to be perfect before running on to the next thing. We didn’t make a product to release a half-developed device right after. It is not sustainable to create to break. A lot of work went into the Mellow from the beginning and we continue to work on its functionality.

Apart from the technical challenges everyone is facing in the electric skateboard market, we also want to address the economical site. As for the general climate of the e-skate market, it turns out to be much smaller than predicted and the struggle to make high tech boards that don’t break has been a struggle for most. Companies who have raised Millions anticipating a huge board sport & mobility market are already off their boards and out of business.

Maintaining and keeping our current customers satisfied with replacements and thorough customer service has been our priority instead of investing in new accessories. We are doing the best we can to make our main product better long-lasting product instead of hopping on the next wave. So let us remind you what we have been up to in R&D to show you that we are not exactly sitting on our hands. Here is a refreshed list of the improvements and developments from the past months and from last year:

Although with our high-quality standards we are always striving for 100%, we have to admit that production of the Mellow Drive had a few teething & a few minor problems.

Reported Issues *Updated*

There have been 4 main issues that Mellow owners reported to us:

1. Batteries were rattling inside of the Drive

2. Batteries dropped out of the Drive

3. Battery wouldn’t charge anymore

4. Drive didn’t work anymore after water entered the system 5. King Pin & Frame weaknesses

6. Connection dropouts

7. Customer demands

These issues didn’t affect all Mellow owners. Many of our customers never reported any issues and still are perfectly happy with their Drive. Depending on the production series and fit of components some Mellow systems were more affected than others.

Detailed Product Improvements *Updated*

Electronics Compartment

Problem: Water Resistance

Improvement: Sealing of the electronics compartment via a rubber layer

We added an extra layer of rubber on top of the electronics compartments to ensure waterproofness. At the same time, abrasion resistance of the lid is increased.

Electronics Compartment

Problem: Water Resistance

Improvement: Reinforcement of electronics compartment silicone seal

The original seal, which is dispensed onto the electronic compartment cover, could bend away in some cases allowing water into the drive. In order to meet this issue, the seal was reinforced to avoid the bending. This measure was confirmed as effective and is in all 2018 Drives.

Electronics Compartment

Problem: Water Resistance

Improvement: Clamping device installed for mounting of electronic compartment lid

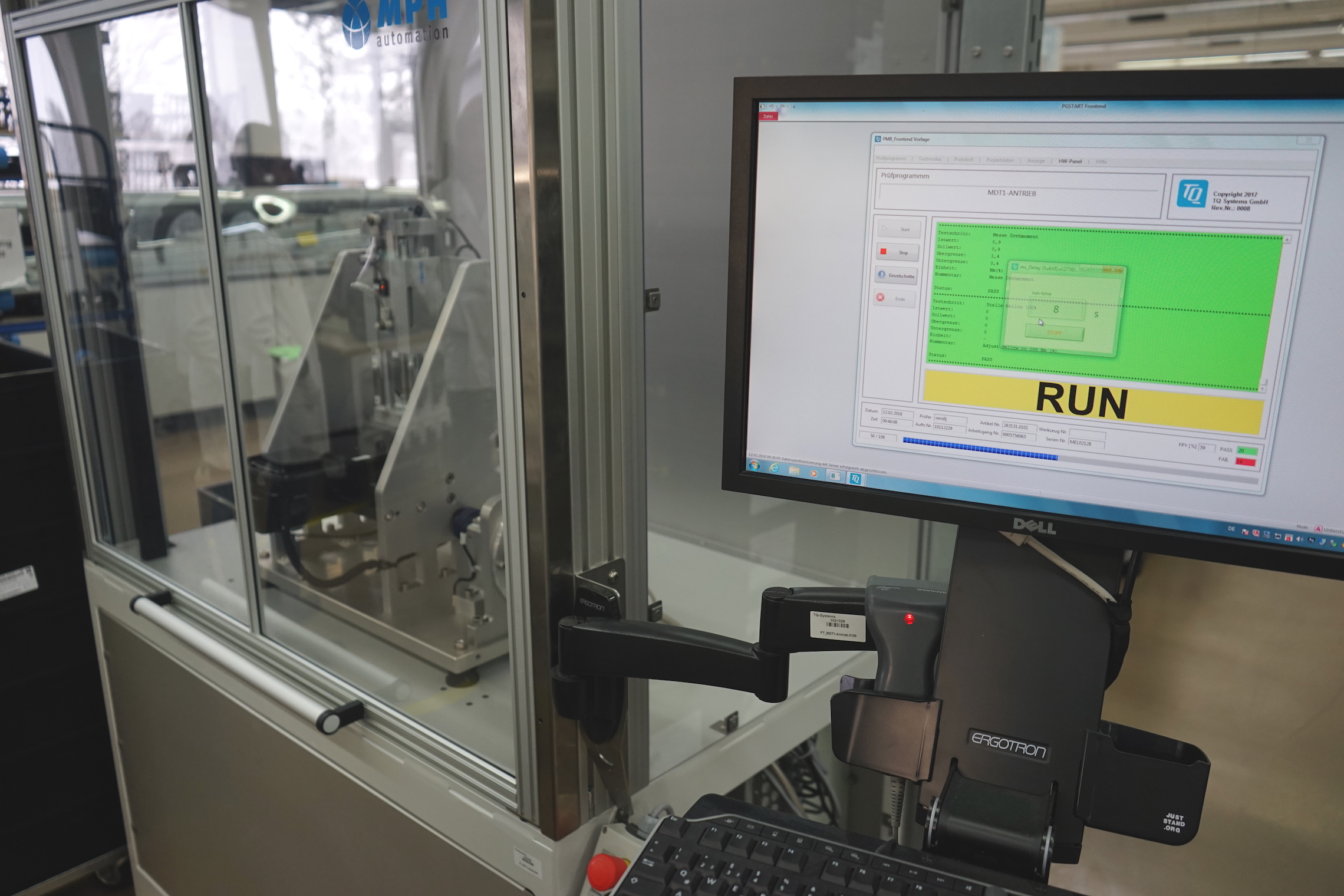

While tightening the screws of the electronic compartment the lid has to be pressed down quite firmly in order to bring the necessary pressure onto the seal. This pressing down used to be done by hand and therefore the water resistance was depending on how well this job was performed. TQ created a clamping device to increase the quality in this step of production. The lid is now pressed down with a defined force by the clamp, which makes this step free of the risks of the "human factor".

Electronics Compartment

Problem: Water Resistance

Improvement: 2x UV resin sealing of electronic compartment screws

The screws of the electronics compartment are now sealed in two layers with a UV curing resin. A UV light system was installed and every screw is separately checked for proper application of the resin.

Electronics Compartment

Problem: Water Resistance

Improvement: Gluing of a plastic insert into the drive done by a robot with extra surface treatment

As there were adhesion issues between the powder coating of the drive and the plastic insert that carries the main battery connector over 250 glueing tests were conducted. The result now is a super-strong bond that is permanently watertight. This was achieved i.e. by a plasma pre-treatment of the glueing area as well as the use of an industrial robot applying the perfect amount of glue to each frame. Also here the "human factor" was taken out in order to achieve reproducible quality.

Drive

Problem: Water Resistance

Improvement: Pressure test

100% of our drives are now pressure tested at the end of production. This means that at the end of the assembly line the drive is "pumped up" with air via the main battery connector and the airtightness is measured. A Drive that holds the pressure is also 100% waterproof.

Drive

Problem: Material Damage

Improvement: King Pin Shell

A few cases of heavy users reported broken King pin´s. Therefore we reinforced the overall Kiong Pin & implemented an additional King Pin shell.

Drive

Problem: Connection interruptions

Improvement: Widen of the Rosenberger connector

Due to a production error of the Rosenberger connector, which resulted in too small connector holes, every Drive connector needed to be revised with a special connector tool.

Drive

Problem: Material Damage

Improvement: Reinforced Frame

In certain cases e.g. wrongly mounted hard risers (not flush with the truck) or heavy usage we reported broken Drives at the rear part of the truck. The frame therefore got reinforced to even support heavier usage of the drive.

Motor

Problem: Water Resistance

Improvement: New bearings & optimised sealing

After previous changes, which included a grease-filling into the gap between the motor and the hanger, we decided to keep sourcing the right bearings. That's why we implemented new bearings with improved waterproofness and optimised the sealings at the same time.

Motor

Problem: Rattling Wheels

Improvement: Improved fit of the wheel on the motors

By tightening the fit of the wheels on our motors we achieved a massive reduction in riding noise and rattling

Battery

Problem: Water Resistance

Improvement: Rubber plugs now have thicker sealing ribs

The height of the sealing ribs on the batteries rubber plugs has been increased. This makes the opening and closing of the plugs a bit more firm but it increases the water-resistance tremendously.

Battery

Problem: Water Resistance

Improvement: Introduction of a rubber gasket under the LED display

Formerly the LED-display was only glued in - now it is equipped with an additional rubber gasket.

Battery

Problem: Broken Snap Lock

Improvement: Introduction of 4 ribs on the backside of the snap lock

In order to increase the strength of the snap lock, 4 ribs were introduced on the backside.

Battery

Problem: Battery Drop

Improvement: Introduction of a shock absorber behind the battery snap lock

As a consequence to a shock the battery's snap-lock could start vibrating, allowing the battery to drop out. We introduced a shock-absorbing pad behind the snap lock of the battery that absorbs the energy of the shock, not allowing the snap lock to vibrate. This way the battery stays in place even on a 1m drop.

Battery

Problem: Rattling / Battery Drop

Improvement: Introduction of lateral pressure pads

Lateral pressure pads now improve the fit of the battery inside the frame and largely reduce vibration of the battery. This measure also reduces the risk of the battery dropping out.

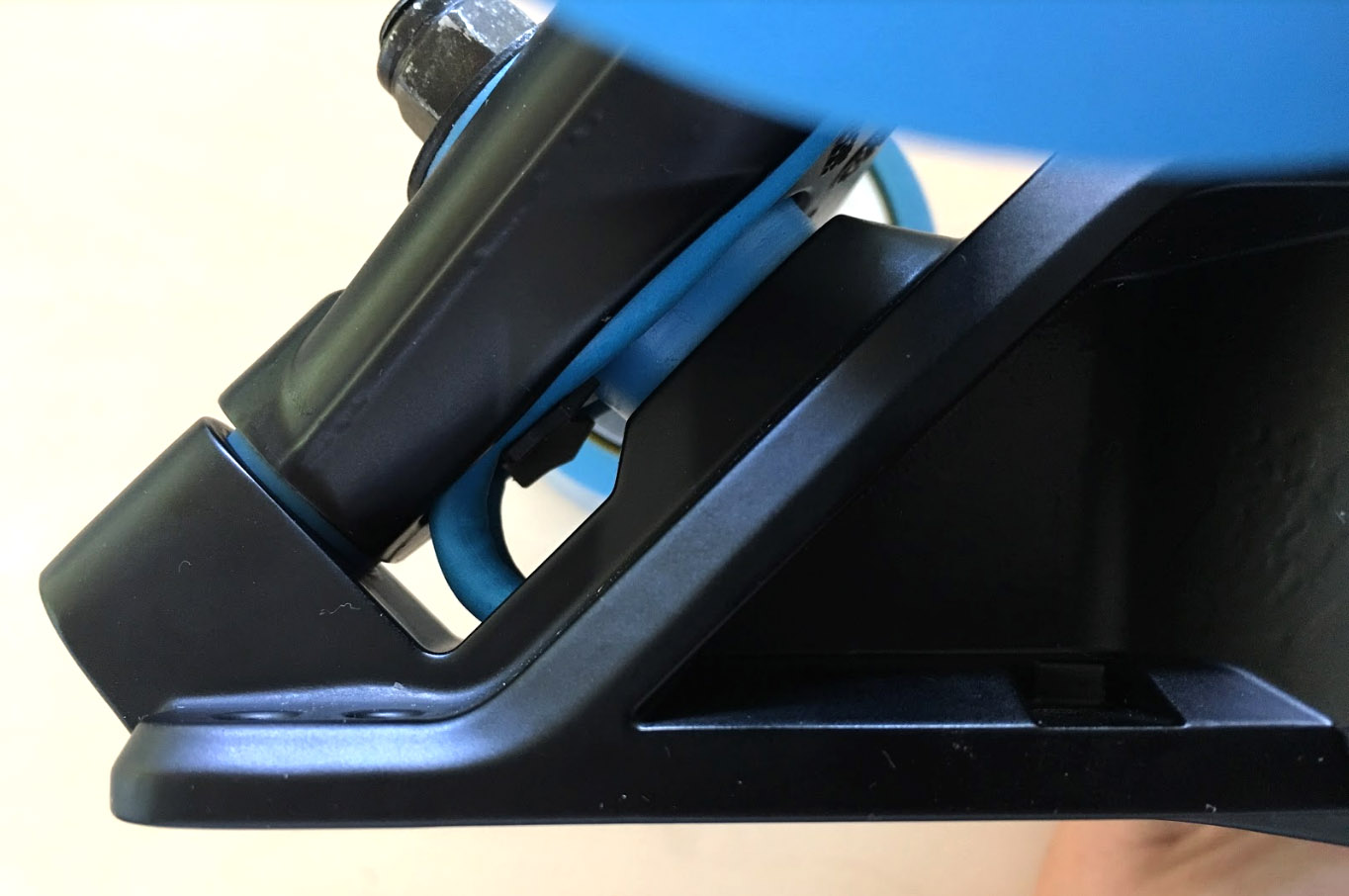

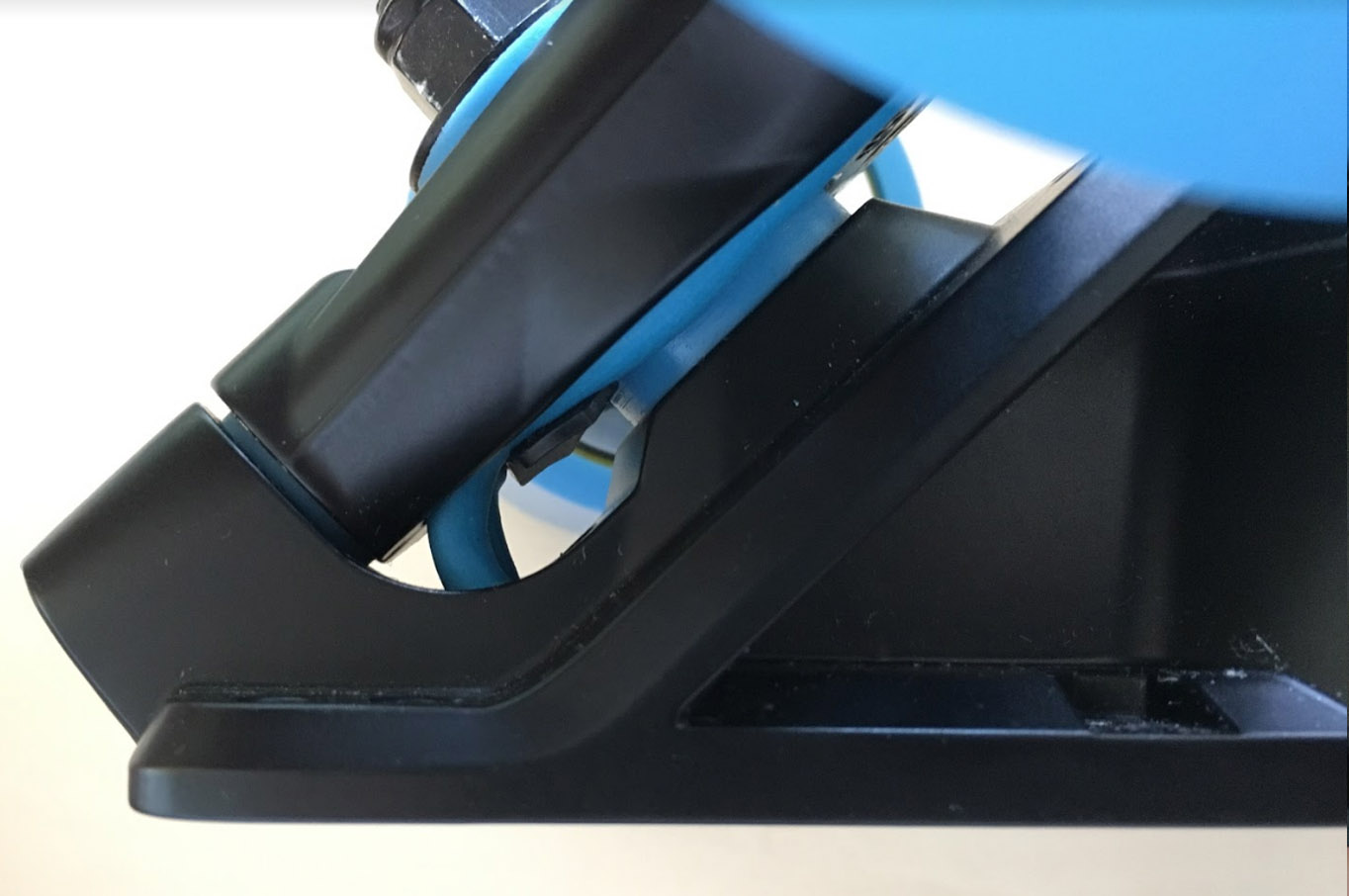

Battery

Problem: Rattling / Battery Drop

Improvement: Improved flatness of the battery housing

By adding ribs beneath the blue over-moulding material we now achieved that the batteries are flatter and therefore fit more tightly in the frame. This reduces vibration, rattling and the risk of battery dropouts.

Battery

Problem: Rattling / Battery Drop

Improvement: Change of blue battery over-moulding material

By changing the blue over-moulding material to a slightly harder compound with less shrinkage (on cooling after injection) we further improved the batteries flatness with the consequences stated above.

Battery

Problem: Rattling / Battery Drop

Improvement: Tightening the battery pockets

At the rear end of the battery left and right of the snap lock has always been two pockets that are now made much smaller in order to firmly bite onto the dedicated metal ribs in the frame. These pockets were there from the beginning as a backup measure for improving the batteries fit and stability and are now being "activated" as we see the necessity.

By tightening the pockets the battery is fixed in position on two additional points now, which reduces the risk of battery dropouts and rattling.

Battery

Problem: Rattling

Improvement: Damping pads

To further reduce noise production and increase the smoothness of the ride, we assembled all batteries including a damping pad inside the battery.

Battery

Problem: Broken lid

Improvement: Improved ultrasonic welding

Due to the design (now screws being used) and large forces working on the lid, we improved the ultrasonic welding by increasing the surface of the battery frame.

Battery

Problem: Burnt-out Charging Fuse

Improvement: Change of fuse to a stronger one

One of the most common battery problems was the burning out of the charging fuse. In order to eliminate this problem, the fuse was replaced by a stronger one for the 2018 models.

Software

Problem: Connection Interruption

Improvement: Software optimization

For better communication between battery and drive to avoid connection dropouts.

Software

Problem: Several customer feedbacks to improve riding experience & safety

Improvement: Software optimization

After hearing you out, we have gone through all the valuable feedback concerning your riding experience. That´s why we did changes to the riding comfort of each mode concerning acceleration and rotational frequency.

Hand in hand with a better riding experience comes to improved safety due to revised temperature derating in drive and battery.

Remote

Problem: Connection Interruption

Improvement: Doubling of Bluetooth signal strength

In order to meet the very rare chance of a connection loss due to an i.e. carbon fibre deck, we doubled the signal strength of our remote control.

Remote

Problem: Decalibration

Improvement: Software and hardware improvements

As some of our remotes would decalibrate over time we introduced several changes into the remotes electronic hardware as well as compensation algorithms that automatically recalibrate the remote on the fly.

Remote

Problem: Decalibration

Improvement: Additional QC-check

At the end of the assembly line, all of our remotes get checked for faulty calibration and are recalibrated if necessary.

Remote

Problem: Decalibration

Improvement: Recalibration feature

If necessary the customer can now recalibrate the remote very easily by a new firmware feature we introduced on the 2018 series. Our support team will guide the customer through the easy steps of recalibration.

Remote

Problem: Lost Connection

Improvement: Increase of transmission strength

In order to meet our customer's complaints of the loss of Bluetooth connection we doubled the transmission strength via a firmware update - so this fix is in all remotes that will be delivered in 2018 and will be available for update to all earlier customers in spring.

Wheels

Problem: Broken core

Improvement: Reinforcement of wheel cores

Wheels

Problem: Urethane being too thin

Improvement: Introduction of 90mm wheels

After many of your were asking for bigger wheels, we introduced a 90mm wheel with a urethane durometer 76A.

Decks

Problem: Only 2 Mellow Decks available

Improvement: Introduction of new deck choices

After all, we are still focusing on the drive unit as our main USP. But we clearly see that working on your feedback we can help to produce the right deck for the right situation. Therefore we introduced some new choices to our store.

Many product improvements over the past months and years helped to refine the product step by step.

Nevertheless, we are expecting further changes to come based on the still unknown riding environments and riding styles. More and more accidents in the overall e-skate market a reported. Not only does it show that e-skating can be dangerous if someone overestimates himself, it makes it, even more, is clear, that every e-skate company still has a long way to go, to ensure the highest safety features.

Safety is the highest priority for us, therefore it´s even more important to focus on revising an existing product instead of raising new capital and follow a higher&fire mentality through growth expectations of Venture Capitalists.

The partnership with the TQ-Group and a slow and organic growth rather helps us to still be a relevant micro-mobility provider in the near future.

We are truly sorry for the inconveniences for everyone who has experienced any troubles with his or her Mellow Drive so far! Be sure that we will replace any faulty component within our 2-year-warranty.

If you want to know if we are available in a shop close to you check out our retailer map or stay tuned via our Mellow News!